Thanks for the quick response as usual, I don’t know how I’d manage without you!

Nikken CNC-401B Vertical CNC Rotary Table

Reconditioned

£12,000.00 ex. VAT

Or weekly from: £134.95

Delivery lead time: Enquire for Estimate

Metric

KG / MM

Imperial

LB / INCH

Weight:

280 kg

Faceplate Size:

400 mm

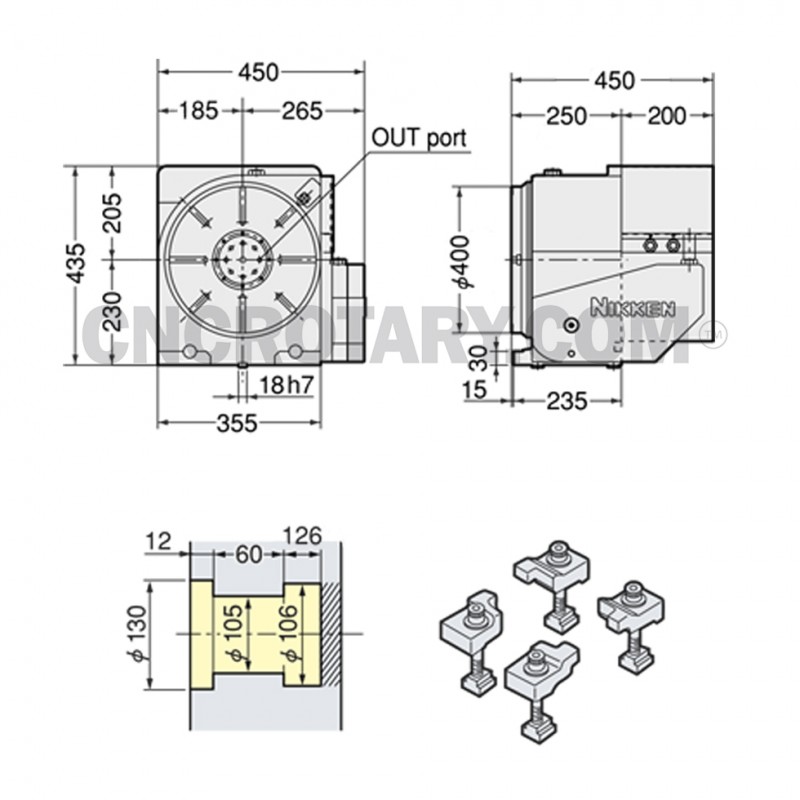

Dimensions:

H: 450.00mm x L: 355.00mm x W: 435.00mm

Warranty:

1 Year

Nikken products carry a standard one year parts and labour warranty when purchased from CNCROTARY. COM. This device may take from 3 to 4 weeks to configure as required.

The Nikken CNC-401B is an ideal device for larger VMC machines with a faceplate diameter of 400mm with options to accept a chuck up to and including 400mm diameter with suitable backplate (not included).

The largest B type model from Nikken with motor mounted to the rear, with higher gear ratio over earlier models increases speed over the vertically mounted motor version type CNC-400V. This unit also has a hydraulic clamping system. The unit has a 130mm spindle nose location with a location depth of 12mm with 105mm directly through the table and a has a centre height of 230mm in the vertical position. This device in the first instance is a vertical mount only device with options for a side mount motor, version which can be found under product code CNC-400V. An excellent carrying capacity of 250kg vertically unsupported and 500kg between centres with a standard tailstock with rotation speeds up to 22. 2rpm dependent on motor selection. (example given is with a 2000rpm motor)Net weight of this device is around 280kgThe Nikken CNC-401B rotary table is offered without motor and can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface”) (motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the rear via the right hand side on this device and is designed to avoid restriction to the Y axis capability and with a large bore available should you want to machine long bar components that need to be mounted through the centre. Please remember however, that being a back mount device the centre bore is restricted to passing through only the depth of the casting (240mm)This range of Nikken devices have Tungsten carbide worm shafts and hardened wheels which can mean less backlash adjustment required over a conventional brass/bronze standard gear.

Not sure this is what you're looking for? View similar items...

Interested in the Nikken CNC-401B Vertical CNC Rotary Table? Enquire today >

You really have been a huge help through all of this. I am sure you must have lots of return business. Great job!

- Brook, Leading Engineering Company, Australia

We have already installed the table in the machine and we are pleased with your work.