Thanks for the quick response as usual, I don’t know how I’d manage without you!

Tsudakoma TN-101 Tilting CNC Rotary Table

£26,995.00 ex. VAT

Or weekly from: £303.59

Delivery lead time: Enquire for Estimate

Metric

KG / MM

Imperial

LB / INCH

Weight:

69 kg

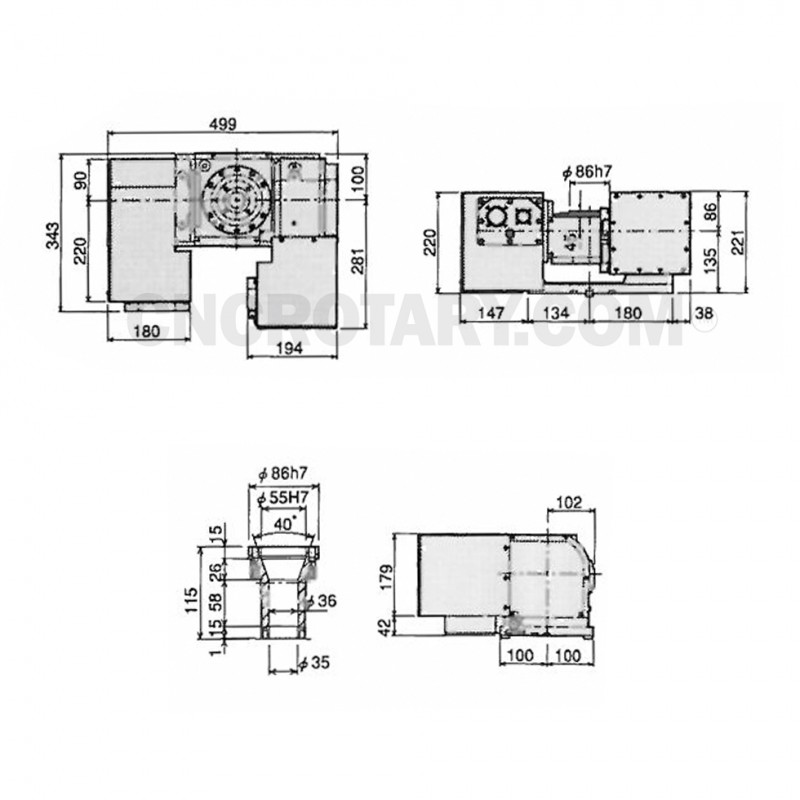

Faceplate Size:

100 mm

Dimensions:

H: 220.00mm x L: 499.00mm x W: 343.00mm

Warranty:

1 Year

The Tsudakoma TN-101 is a high speed rotary table tilting device, ideally suited to small drilling and tapping centres or for small VMC machines, with a spindle nose diameter of 86mm with options to accept a 135mm (5. 35”) faceplate or can accept a standard or power chuck.

The latest TN tilting range from Tsudakoma, with major developments over earlier models with major increases in speed and power transmission, with high power pneumatic clamping system. The unit has a 55mm spindle nose location with a generous location depth of 15mm with 35mm directly through the table and a has a centre height of 135mm in the vertical position (90 degrees) and 180mm in the horizontal position (0 degrees) without faceplate, 205mm with faceplate. This device is around 500mm in overall width which would ideally suit a wide range of machine tool bed widths and an overall height of 221mm. The unit has a standard tilting range of -17 to + 107 degrees. An excellent carrying capacity of 20kg through the whole tilting range and 35kg horizontally or between centres and speeds of up to 41. 6rpm in the rotary axis and 16. 6rpm in tilt dependent on motor selection. Net weight of this device is 69kg. The Tsudakoma TN-101 CNC rotary tilting table without motors, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th / 5th ;axis interface” in the machine) and machine interface costs (if you do not have the additional axes fitted). Rotary axis motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the tilt axis motor is mounted in a rear facing direction on the far side of the device and should not have any bearing on traverses. This range of Tsudakoma devices now come with dual lead full depth worm and wheel, which means that there is less load on individual teeth improving wear and torque performance over and above the conventional standard gear. Tsudakoma is one of the oldest and original manufacturers from Japan and in our experience build a very fine device with a very long service life, probably greater than those we have experienced from other Japanese makers. Tsudakoma products carry a standard one year parts and labour warranty and have a full working partnership with CNCROTARY. COM. This device may take from 2 to 3 weeks to configure as required.

Not sure this is what you're looking for? View similar items...

Interested in the Tsudakoma TN-101 Tilting CNC Rotary Table? Enquire today >

You really have been a huge help through all of this. I am sure you must have lots of return business. Great job!

- Brook, Leading Engineering Company, Australia

We have already installed the table in the machine and we are pleased with your work.